Besides MINK claw vacuum pumps, tested R5 rotary vane vacuum pumps are applied Every time greater vacuum amounts are required. If materials are to get transported in reasonably large volume, the primary decision could be SAMOS aspect channel blowers or TYR rotary lobe blowers.

Weighing of the massive baggage station to tell the procedure about the level of powder released. The entire significant bag emptying system is put in on four load cells. As a way to stay clear of any chance of your framework tipping about, the wheelbase is improved.

One more benefit of employing vacuum above pressure conveying is There is certainly significantly less lack of material. As an example, If your pipe community contains a leak, it will eventually pull the ambient environment inward in lieu of expelling it outward, which while in the later (pressurized line) would trigger a dusty mess.

Initially, the materials is billed in the force vessel with the rotary air lock. Once the stress vessel is loaded, the inlet and vent valves shut and seal, and highpressure air is progressively introduced into the tension vessel. The superior-force air conveys the material towards the receiver, in which the air and the material are separated by a filter or other system.

Find out how Floveyor bag dump stations safely and securely and successfully vacant bulk luggage and integrate with the remainder of your production line.

You can find also a lump breaker which breaks up the lumps that can form within the materials over the generation or transportation process. The framework can be positioned on load cells in order to Examine the weight and is supplied with electro-pneumatic Management panels with PLC. Jumbo bag loading system, or also referred to as jumbo bag filling stations, could be created to work as both manual or an automated system. Jumbo bag loading system assists your means of packaging to be pretty efficient, rapidly filling and economical for agricultural and industrial materials. This also increases plant security by decreasing the amount of Actual physical handling necessary to load and unload the packaged material due to the fact They are really intended to be moved by the use of a forklift or hoist. There are several different apps for jumbo bag unloading and loading system for instance mixer loading, silo filling, bulk truck loading, weighing system, packaging system, manufacturing line feeding, batching, and dosing system. Consult with with ETST to prepare the fittest jumbo bag unloading and loading system to your demands.

To maneuver materials with the feed stage into the load issue, conveyors make use of strain dissimilarities attributable to a vacuum. The bulk solids are pulled to 1 conclude by adverse strain and air velocity in the inlets.

Horizontal and vertical lifting, swiveling and rotating - what at first look appears being standardised procedures, in a short time will become a decisive success Think about the creation course of action.

Our Batch Weighing System, comprises of one weigh controller that controls and weighs couple of various materials which constitute a batch. It helps make confident that correct quantity of material is discharged to finish a batch.

In addition to for transporting granules in plastics processing purposes. Additionally, vacuum conveyors can here manage moist materials. For instance, within the disposal of soaked squander or even the transport of bark mulch. Pneumatic overpressure conveying

Pneumatic conveying systems normally drop into certainly one of two broad types: dense period or dilute phase. Though equally sorts of systems complete the identical function, the other ways by which ... three October 2024 Read through far more

Dilute section (also called stream-flow) pneumatic conveying is most effective in comparison to what takes place in a car parking zone with a blustery working day. Whilst going for walks to your automobile right after perform, you’re blasted with dust and Grime that’s been picked up off the bottom by rapidly-transferring wind. The more quickly the wind, the more material hits you. As the wind speed picks up, larger dirt particles also develop into entrained during the wind.

Even so, vacuum conveyors usually are not a good alternative if you need to move materials extensive distances. Mainly because they function with pressures at or below atmospheric pressure (fourteen.seven psig), vacuum conveyors are limited to a optimum horizontal distance of 50 ft and also a greatest horizontal distance of 200 ft. The helpful horizontal distance is usually diminished by vertical distances and piping bends.

The essential components of the strain system are a rotary air lock feeder valve, a substantial tension air compressor system or simply a low-strain constructive displacement blower or fan to serve as the ability source. A strain vessel, the conveying line, and the receiver make-up the stability in the system.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Kelly Le Brock Then & Now!

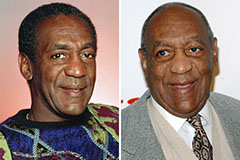

Kelly Le Brock Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!